Product Introduction

This kind of exhaust heat utilization system takes exhaust heat from boiler as heat source, which can reduce investment on heat supply and makes no secondary pollution to environment. Traditional dryers always apply coal as fuel, which will consume too much coal and cause much environmental pollution. At present, there are many common problems existing in drying industry, such as high investment, high energy consumption and low efficiency. In addition, majority of enterprises cannot make full use of exhaust heat.

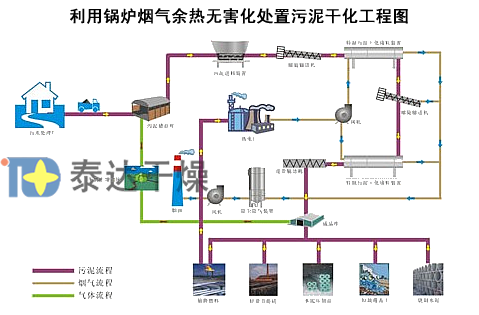

Exhaust heat utilization is one of Zhengzhou Taida Group’s patent technology, which takes exhaust heat from boiler as heat source. Accordingly, it cannot only reduce investment on coal, but also reduce environmental pollution. This technology positively responses to national call on environmental protection. At present, Zhengzhou Taida exhaust heat utilization technology has been applied to sludge and coal slurry industries and save a great amount of investment on heat supply. Great economic profits brought by exhaust heat utilization technology has been produced to many enterprises. This kind of technology can make full use of exhaust heat, flue gas and steam produced from power plants and other combustion systems to dry relevant materials, which greatly reduce environmental pollution.

Product Superiority

Great flexibility

Drying period can be adjusted flexibly according to types of materials. It cannot only be used to dry materials with high moisture, but also can do continuous production. Besides, it can carry out intermittent production according to customer’s special requests.

Precise and flexible drying system

We can design insertion board according to different drying quality and drying curve. Pushing shovel and discharging shovel plate can make the system realize best drying effect. The retention time of raw materials in drying machine can be achieved by clapboard in discharging chute.

High automation level

This system can carry out continuous production. For some special production process, it can also carry out intermittent production. The whole production environment is very clean and with low noise. For those materials with different specific gravity, different moisture and different shape, this system can always fulfill good drying effect.

Flexible drying mode

This system can carry out both concurrent drying and counter-current drying. Therefore, it can be applied to thermal-sensitive materials. With great flexibility and high automation level, this system can do both continuous and intermittent production. Drying period can be adjusted according to different moisture content and materials’ quality.

Convenient for transportation and installation

This whole set of machine is set on bearing with independent ba

Wide application

Whatever specific gravity, particle size, shape and bulk density of raw materials are, this system can get very superior drying effect.

Occupy less area, compact production process

This whole production needs fewer auxiliary equipment and occupies less area. With compact production process, this equipment holds less quick-wear parts. This set of equipment is very easy to install.

Working Principle

This drying system is mainly composed of heat source, loader, feeder, rotary drum, crusher, discharger, induced draft fan, discharger and electrical cabinet. After dehydration, wet materials will be sent to dryer and stirred by lifting plates which are evenly distributed in rotary drum. Thus, raw materials will contact with hot air evenly, which speeds up heat and mass transfer. In drying process, in the function of inclined lifting plates and hot media, final products will be sent to star discharger.

Technical Parameter

| Model |

Rotary Speed r.pm |

Main Power kw |

Heat Transfer Area m2 |

Drying Capactiy kg water/m2h |

Overall Dimensions mm |

Weight T |

| TDZG50 | 5~8 | 5.5 | 50 | 4.7 | 8032×1712×2250 | 9.0 |

| TDZG100 | 5~8 | 7.5 | 100 | 4.7 | 9100×1912×2470 | 14.0 |

| TDZG150 | 5~8 | 11 | 150 | 4.7 | 8500×2212×2810 | 18.5 |

| TDZG200 | 5~8 | 11 | 200 | 4.7 | 10000×2212×2810 | 20.0 |

| TDZG250 | 5~8 | 15 | 250 | 4.7 | 10200×2212×2810 | 23.0 |

| TDZG300 | 5~8 | 22 | 300 | 4.7 | 10784×2488×3383 | 26.0 |

| TDZG350 | 5~8 | 30 | 350 | 4.7 | 12048×2488×3383 | 28.0 |

| TDZG400 | 5~8 | 30 | 400 | 4.7 | 13048×2488×3383 | 30.0 |

| TDZG500 | 5~8 | 45 | 500 | 4.7 | 11298×2982×3965 | 40.0 |

| TDZG600 | 5~8 | 75 | 600 | 4.7 | 12298×2982×4165 | 45.0 |

| TDZG700 | 5~8 | 75 | 700 | 4.7 | 13298×2982×4365 | 51.0 |