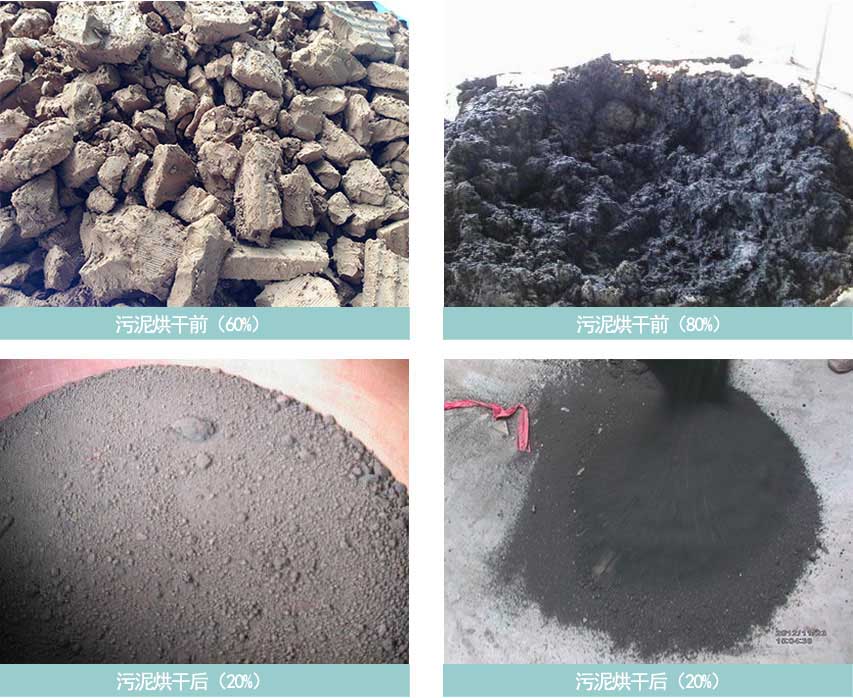

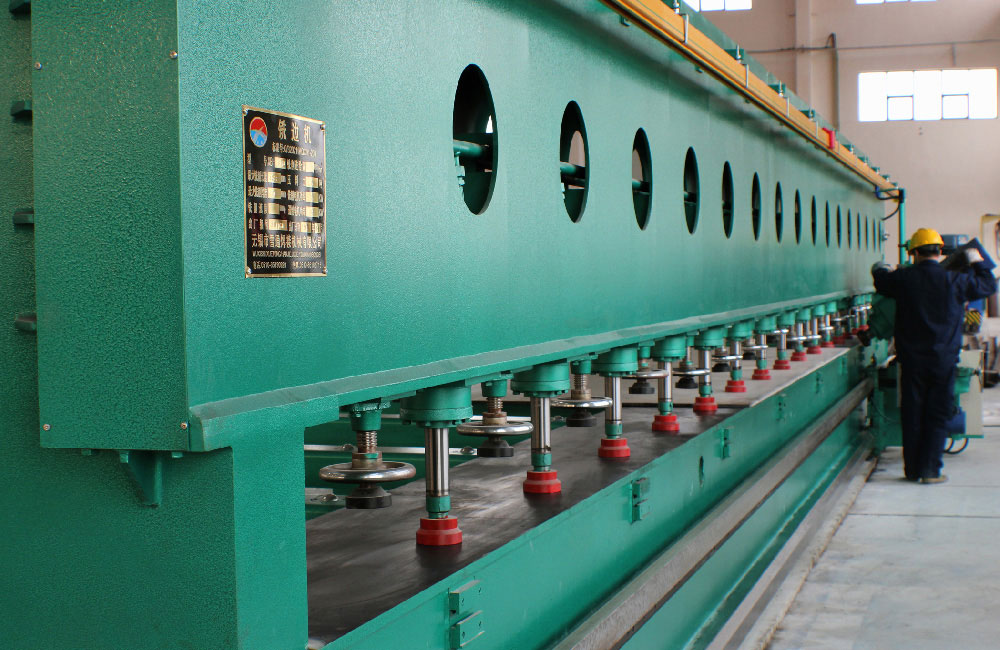

Aimed at desulfurized and chemical sludge, Zhengzhou Taida developed out a unique power plant sludge drying system solution which is ba

【Application range】:applied to deal with desulfurized and chemical sludge from various power plants, denitration sludge from boiler enterprises. It can also be applied to viscous and high-moisture materials.

【Application materials】:various sludge, desulfurized gypsum, toxic and heavy me