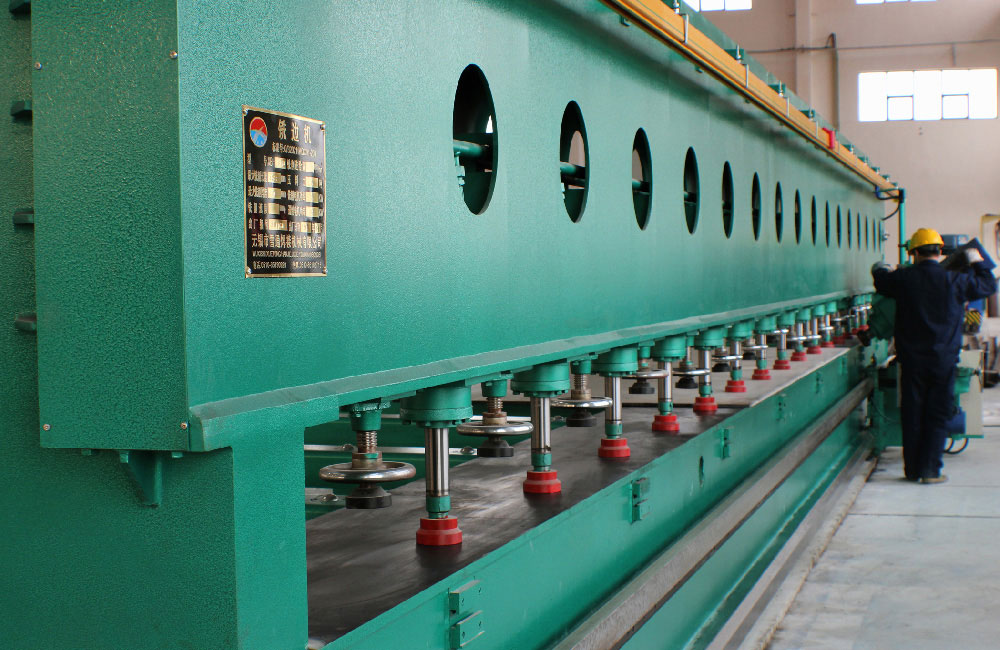

Desulfurized gypsum is widely applied to building material industry. Through different ways, it can almost replace majority of natural gypsum. Comprehensive disposal technology in china has taken steps. The utilization prospect contains a great market opportunity.

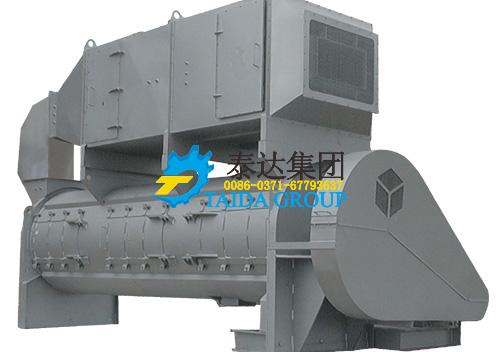

applied to various thermal power plants, ceramic industry, hospital industry and mould manufacturing industry. Meanwhile, it can also be used to dry high moisture and viscous materials.