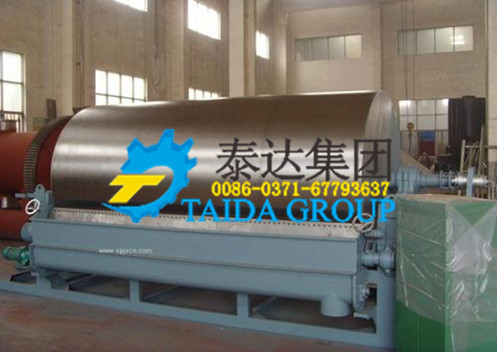

Product Introduction

Taida yeast drum dryer is single cylinder dryer which can be used in a variety of pulp drying, especially suitable for the brewery recycling waste yeast. Different specifications of the dryer can meet the needs of the annual output of ten thousand to eight hundred thousand brewery. This machine is suitable for food, chemical, pharmaceutical and other industries in the drying process. Drum is made of high-quality cast iron, which is deeply processed and polished and have the advantage of corrosion prevention and non-pollution.The design of heat conduction could largely reduce the heat loss from heat media, raising the heat efficiency to 70% and lowering the energy cost.Compact distribution, space saving, convenience operation and maintenance.Yeast dryer is designed based on the German machinery technique and local conditions, which has outstanding features.

Product Superiority

1. Drum is made of high-quality cast iron, which is deeply processed and polished and have the advantage of corrosion prevention and non-pollution.

2. The design of heat conduction could largely reduce the heat loss from heat media, raising the heat efficiency to 70% and lowering the energy cost.

3. Compact distribution, space saving, convenience operation and maintenance.

4. Yeast dryer is designed ba

5. This type dryer adopts low-temperature and fast drying process which can guarantee the activity of raw materials.

6. The part which contacts with raw materials is made of superior casting iron.

7. Yeast scraper dryer also holds many other advantages, such as anti-corrosion, no contamination, high thermal efficiency and less energy consumption.

8. This machine holds compact structure, less area occupied and simple operation process.

9. Ba

Working Principle

Yeast rotary scraper dryer is composed of many components such as dryer body, fr

Yeast rotary scraper dryer adopts a kind of indirect heating mode to heat materials and vaporize moisture. It adopts steam to carry out heating process. The outer surface of dryer cylinder is a kind of bright and clean hollow cylinder which has been processed. With the transmission of driving device, dryer drum will rotate along axial and the rotation speed is adjustable. Yeast slurry will be preheated to about 50 degrees in the preheating tank. Then, yeast slurry will be conveyed to material leaching tank by delivery pump. Dryer cylinder will be leached about 60 to 80 mm. outer shell of rotary dryer cylinder will be coated a la

Technical Parameter