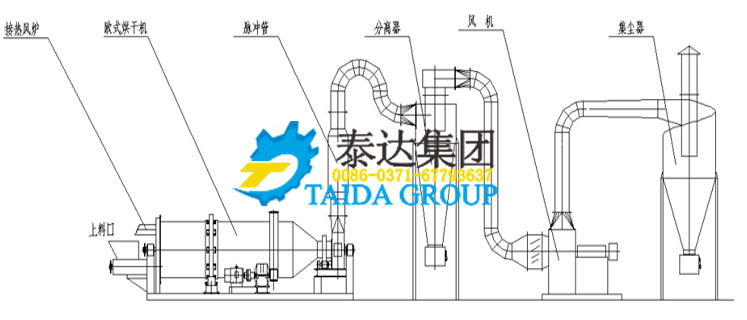

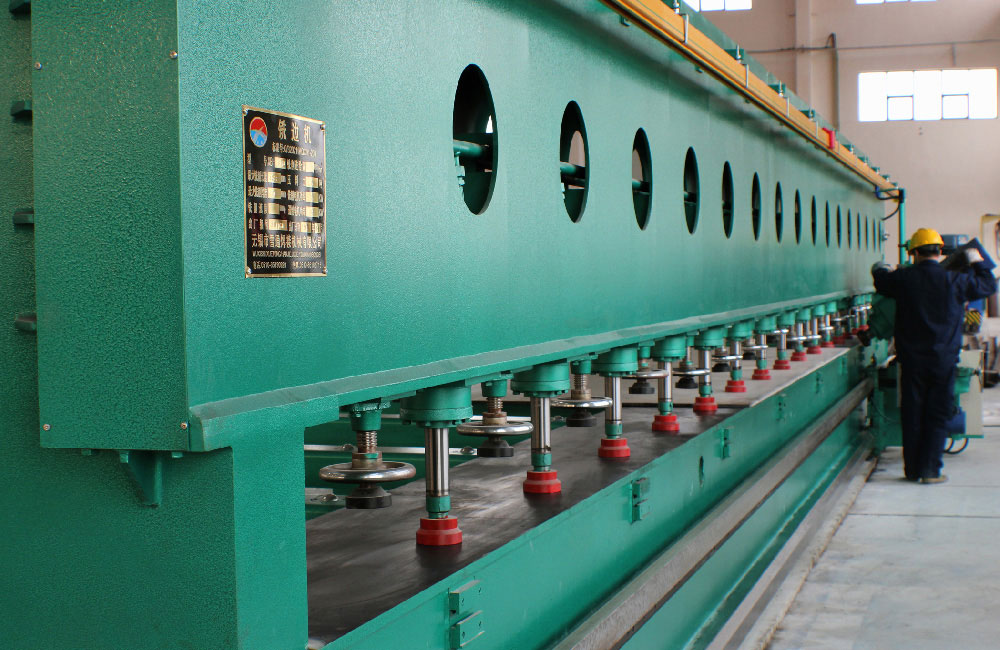

Bean dregs is a kind of materials with high compound water content and oil content. It is hard to eliminate the moisture of bean dregs. Aimed at features of bean dregs, Zhengzhou Taida developed whole set of European style dehydration and drying system. The whole drying system can fully make use of thermal energy. Bean dregs can be heated evenly. Final products are with good color. This whole drying system consumes less energy compared with traditional drying machine.

【Application range】:

used to dry viscous and high-moisture feed factory, livestock farm and agricultural households.

【Applicable materials】:

it is suitable for drying various bean dregs, tofu residue, bean pulp and brewer grains.