Product Introduction

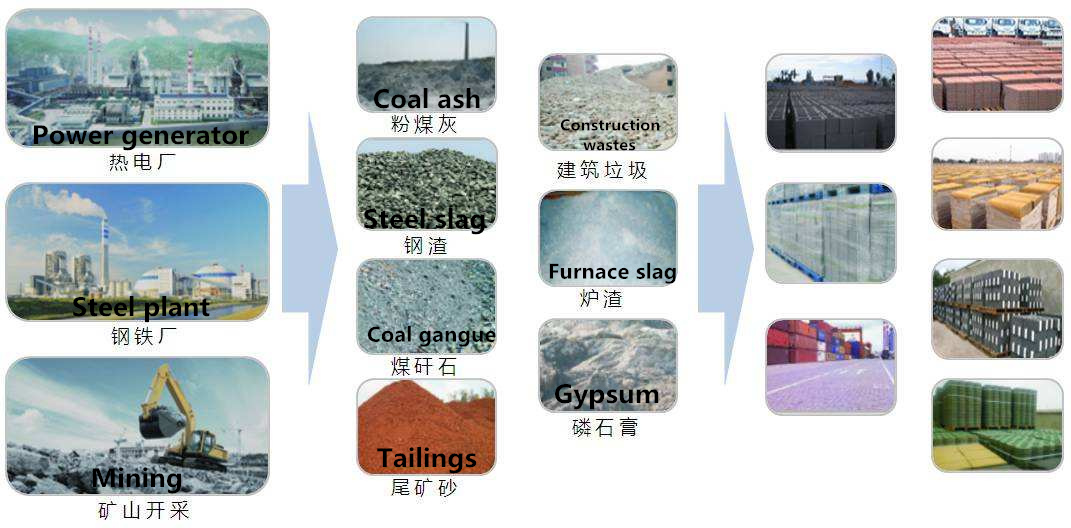

Coal ash is a kind of volcanic ash-like mixed material formed by pulverized coal after high temperature combustion. It is a coal-fired power plant that grinds coal into coal powder below 100 microns, which is sprayed into the furnace with preheated air to form a suspended state, which produces high-temperature flue gas mixed with a large amount of incombustible materials, which is captured by a dust collecting device. Fly ash. China is a big coal producer, so the amount of fly ash per year is also very impressive. Under this circumstance, the comprehensive utilization of fly ash, turning waste into treasure and turning harm into profit has become an important technical and economic policy in China's economic construction. It is a solution to the contradiction between China's power production environment pollution and lack of resources. The important means is also one of the tasks that power production is facing. After development, the fly coal ash is processed by the fly coal ash dryer, and it can be widely used in various departments such as construction, building materials, and water conservancy.

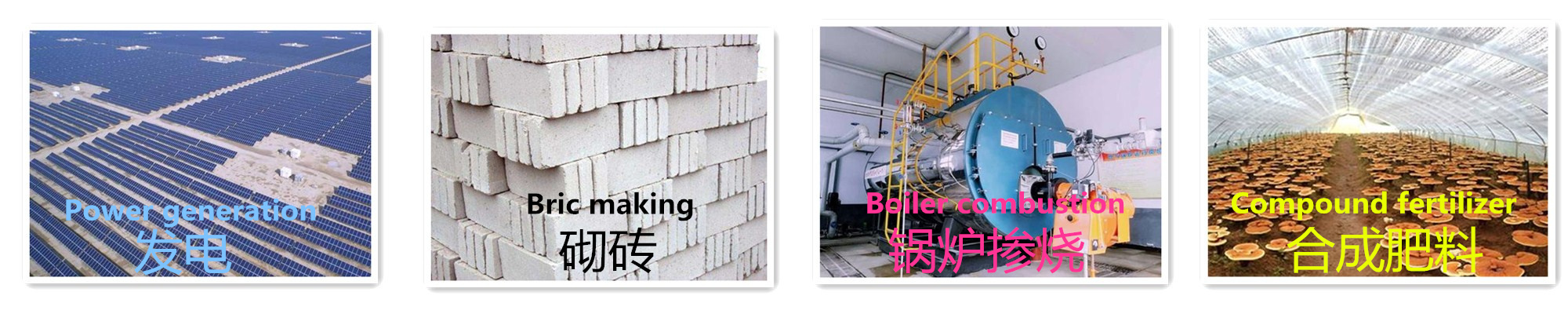

Main applications of dried coal ash, it is divided into major severn types in China:

1. Fly coal ash aerated concrete: Fly ash aerated concrete is a new type of lightweight insulation and energy saving wall material.

2. Fly coal ash concrete hollow block: In recent years, fly ash concrete hollow blocks have developed rapidly. The main raw materials are fly ash, aggregate, cement, etc. The raw materials are made by processes such as metering, mixing, forming and curing.

3. Cement fly coal ash expanded perlite concrete insulation block: The process is basically similar to the fly ash concrete hollow block.

4. Fly coal ash concrete paver: Fly ash concrete pavement bricks are made of cement and fly ash as mixed cement and coarse aggregate. The raw materials are made by metering, stirring, forming and curing. The molds can be changed into square bricks, interlocking pavers and antiques. Bricks, green grass, bricks, road blocks and other shapes of pavement bricks.

5. Fly coal ash bricks: Fly ash bricks are prepared by using fly ash and lime as main raw materials, adding appropriate amount of gypsum and aggregate, preparing by billet, pressing forming, and curing with high pressure or atmospheric pressure steam.

6. Fly coal ash ceramsite and concrete products: Ceramsite is an artificial light aggregate. Fly ash ceramsite is made of fly ash as the main raw material, processed into balls, sintered or swelled, called fly ash ceramsite.

7. Fly coal ash concrete lightweight partition board: Mainly on the basis of light wallboard, add some fly ash to produce mild partition board when making ingredients, or produce mild wall board with cement fly ash foam concrete.

8. In addition, fly coal ash can also be used in synthetic fertilizers: as waste water, flocculant for waste gas, and the like.

Product Superiority

-

Energy saving

Taida coal ash drying system provides good prospect for coal ash comprehensive utilization. It holds wide application range.

-

Complete drying system

Whole coal ash drying line adoopts compelete drying system. With simple structure and good heat transferring effect.

-

Flexible operation

It allows large flucation for the product flow,which will not affect product quality and provides convenience for cleaning.

-

Small resistance

It can be used to dry particle materials, even for thos materials with large stickiness.

Working Principle

Coal ash dryer working principle: wet coal ash will be sent to horizontal rotary cutting machine by conveyor for crushing, which can avoid drying problems caused by large bulks and improve drying effect. Crushed materials will be sent to drum dryer where there are many lifting plates arranged in screw shape set in drum. Coal ash will be repeatedly lifted and scattered under the function of drum rotation. Striking device set on drum wall will further crush materials. Lifted materials will fully contact with hot air for heat exchanging and moisture evaporation. Dried products will be discharged from outlet. Dusty gas will be recycled by dust removing machine.

Technical Parameter

| Model | Drum diameter(M) | Drum length(M) | Drum slope(%) | Motor power(kw) |

Drum rpm (r/min) |

Occupation area(m²) |

| TDGT-12100 | 1.2 | 10 | 3-5% | 7.5 | 3-8 | 100 |

| TDGT-15120 | 1.5 | 12 | 3-5% | 10 | 3-8 | 150 |

| TDGT-15150 | 1.5 | 15 | 3-5% | 18.5 | 3-8 | 200 |

| TDGT-18120 | 1.8 | 12 | 3-5% | 11 | 3-8 | 260 |

| TDGT-22120 | 2.2 | 12 | 3-5% | 18.5 | 3-8 | 260 |

| TDGT-22140 | 2.2 | 14 | 3-5% | 18.5 | 3-5 | 300 |

| TDGT-22160 | 2.2 | 16 | 3-5% | 30 | 3-5 | 300 |

| TDGT-24140 | 2.4 | 14 | 3-5% | 30 | 3-5 | 350 |

| TDGT-24180 | 2.4 | 18 | 3-5% | 37 | 3-5 | 400 |

| TDGT-24220 | 2.4 | 20 | 3-5% | 37 | 3-5 | 450 |

| TDGT-30200 | 3.0 | 20 | 3-5% | 55 | 3-5 | 500 |

| TDGT-30220 | 3.0 | 22 | 3-5% | 75 | 3-5 | 500 |

| TDGT-40250 | 4.0 | 25 | 3-5% | 210 | 3-5 | 800 |