Aimed at Taida sewage sludge, Zhengzhou Taida developed a set of sewage sludge drying solution. This technology is ba

【Application range】:

【Applicable materials】:

Welcome to Official Website of Zhengzhou Taida Drying Equipment Co,.Ltd!Please call 0086-371-86565118 for more information.

Aimed at Taida sewage sludge, Zhengzhou Taida developed a set of sewage sludge drying solution. This technology is ba

【Application range】:

【Applicable materials】:

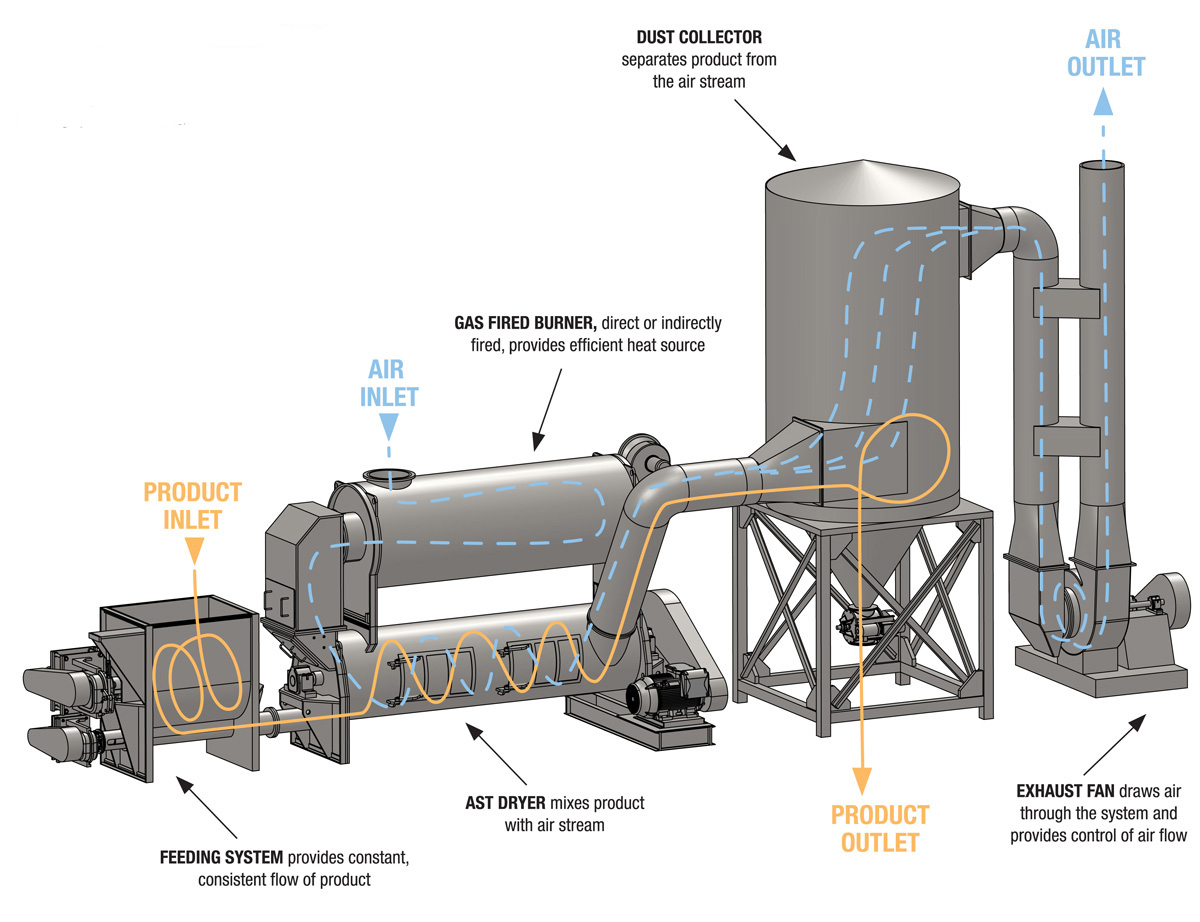

1. This drying machine holds great generalization performance. Even, can be used to materials which are difficult to deal with.

2. This whole drying system can be simply controlled. With wide range of fuels available, such as natural gas or oil, the combustion speed can be controlled by temperature instrument at dryer’s discharge end.

3. The drying system adopts advanced drying technology at present. It holds better drying effect.

4. This drying system can dry wide range of materials, from low-solid content pulp to low moisture powder. It can be used to deal with almost any kind of materials.

5. Raw materials’ routine can be controlled. Finally, the state of final products can be controlled, dry powder or pellet materials.

6. Taida dryer can adopt coal, electricity, oil and natural gas as heat source. Drying hot air can be primary or indirect hot air.

7. Handling capacity of raw materials ranges from 100 kg per hour to tons per hour.

8. With complete auxiliary system, this system can be used to solve your demands of crushing, drying, pelletizing and odor disposal.

9. With compact structure, this system occupies less area. It holds less noise and less vibration. With the cooperation of combustion furnace and tail gas purification system, it can save a lot of energy. No pollution to environment.

Air-swept dryer adopts advanced technology. This machine can be used for almost any kinds of materials, from low solid-content pulp to low mist powder state. Materials’ routine in dryer can be controlled. Therefore, this machine can be used to dry fine powder or low moisture granular materials. There are three individual working zones to control drying speed. Central zone decides residual content and physical size of final products. Although there is high temperature difference existing in this type of dryer, it is same as majority of instant dryer whose product temperature is lower than that of wet ball. This type of dryer can adopt oil or gas as heat source which is usually connected with drying cylinder. Final products can be directly collected from the end of dryer, separator or bag filter. This series of dryer contains 9 sizes. Evaporation speed can reach to 8 tons per hour.

| No. | Sludge characteristics | Solutions |

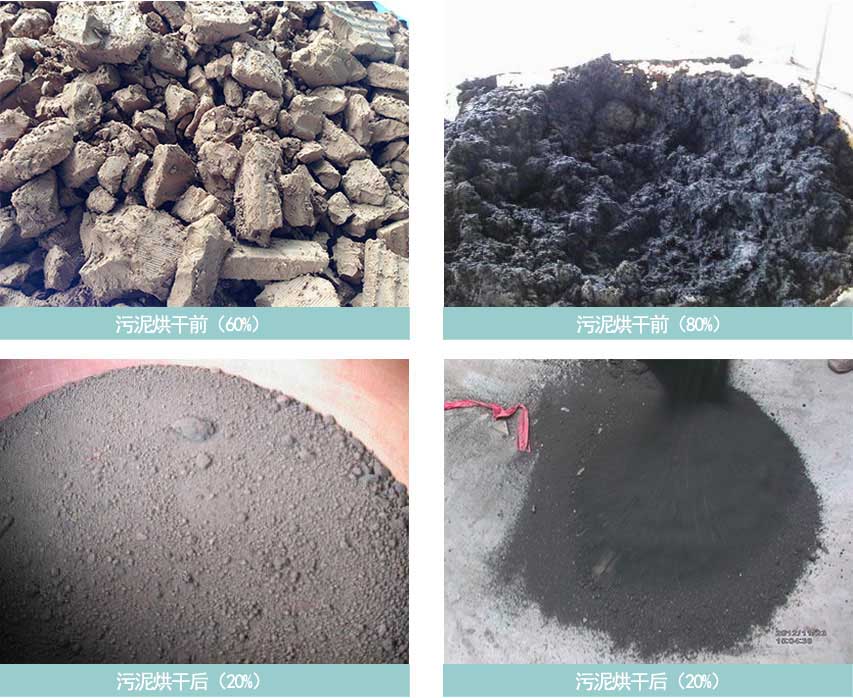

| 1 | High moisture content | TDOSC air swept drying system can dry moisture of high-moisture content and viscous materials to standard level. |

| 2 | Caking | TDOSC air swept rotary wing drying system integrates crushing and drying into a whole. |

| 3 | Poor fluidity, feeding jams | Patent technology; designed for high moisture and viscous materials. |

| 4 | Big viscosity, wall sticking and not easy to clean | Patent technology; designed for high moisture and viscous materials. |

| 5 | Materials are easy to lump; moisture hard to evaporate, | Patent technology; designed for high moisture and viscous materials. |

| 6 | Give off odor | With anti-explosion device and good seal structure; add one deordorization device for exhaust gas dust collecting system; |

| 7 | With corrosive components |

A:In raw material system, materials will mix with neutral materials; B: TDOSC air swept rotary wing drying system are made of stainless steel design, if there is no special request from customers. |

| 8 | Feed head easy to be burnt out | Integrated drying body; durable stainless steel design. |

| Revolutionary product, fifth generation drying technology for high moisture and viscous materials!!! | ||

Sales Hotline:0371-67793637

Technical Support:15515557076

Whatsapp:008618539990967

Email:vip@tdaxy.com

Factory Address: No.198, Longding Industrial Park, Lianhua Road, High-Tech Zone, Zhengzhou City

Email:vip@tdaxy.com Technical Consult:86-18539990967

Municipal Sludge Drying Equipment

Viscous Material Drying

All Rights Reserved Zhengzhou Taida Drying Equipment Co,. Ltd