Present development situation of papermaking sludge drying system

Papermaking process consumes much resources and energy. During the process, a great deal pollutants is produced, which seriously affects environment. With the expanding of production scale, ecological problem and social problem gradually arise.

Waste residue and sludge produced from papermaking process hold high moisture content, over 60%. They presents silt state. With complex ingredients, it is hard to deal with papermaking sludge. At present, many enterprises prefer to simply landfill and pile up. With the increase of governmental supervision, people gains more and more awareness of environmental protection. Enterprises become more and more responsibility to society and environment. Various circular exploration and application become more and more popular. In general, complete and mature solid wastes disposal chain hasn’t been formed. Utilization technologies for various wastes just start.

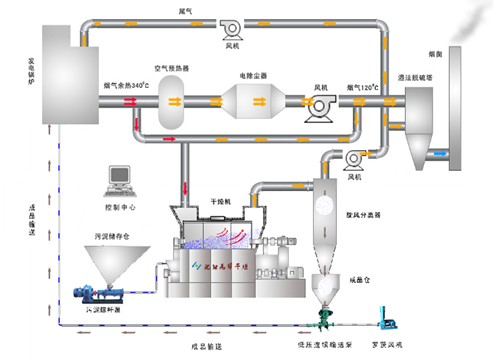

Taida energy-saving and efficient papermaking sludge drying solution

Has been specialized in sludge drying technology for many years, aimed at toxic and harmful sludge produced in industries, combined with real situations in different fields and summarizing up traditional disposal methods, Zhengzhou Taida group developed out a set of complete set of harmlessness and recycling system for toxic sludge.

Customers can:

1. Customers can choose flexible heat sources, such as coal, electricity, microwave, natural gas, LPG and diesel.

2. After drying, final products can be used as fuel for boiler. dried sludge can also be used to make bricks, landfill and compost to realize

3. Environmental friendly and energy-saving;

After drying process, what field can the dried sludge be applied to?

1. Papermaking residues and dehydrated sludge can be used as new type building materials. Customers can choose flue gas to dry wet sludge in order to build favorable condition for sludge mixing rate.

2. After drying, papermaking sludge can be used to make compost. Papermaking sludge is rich in natural organism and heavy metal.

3. Papermaking sludge can also be applied for incineration. After dehydration and drying, dried sludge can be sent to special boiler as fuels.