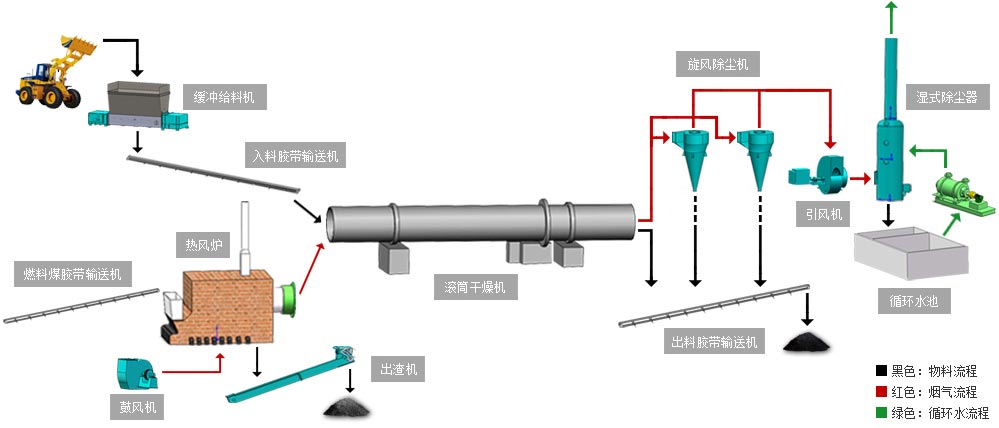

Coal slurry is a kind of material which holds high moisture and high stickiness. During drying process, coal slurry will be sent to coal dispersing zone. After dispersing zone, there will be four zones set for the dryer, material-guiding zone, cleaning zone, lifting plate zone and discharging zone. Accordingly, drying process can be achieved perfectly.

【Application range】:

all kinds of coal mine, coal washing plant, mining industry

【Applicable materials】:

can be applied to dry various coal slurry, raw coal, fancy coal, lignite and etc. this new type rotary dryer has been successfully applied to coal mine, coal washing plant and fuel industry.