【Application range】:

【Applicable materials】:

Welcome to Official Website of Zhengzhou Taida Drying Equipment Co,.Ltd!Please call 0086-371-86565118 for more information.

【Application range】:

【Applicable materials】:

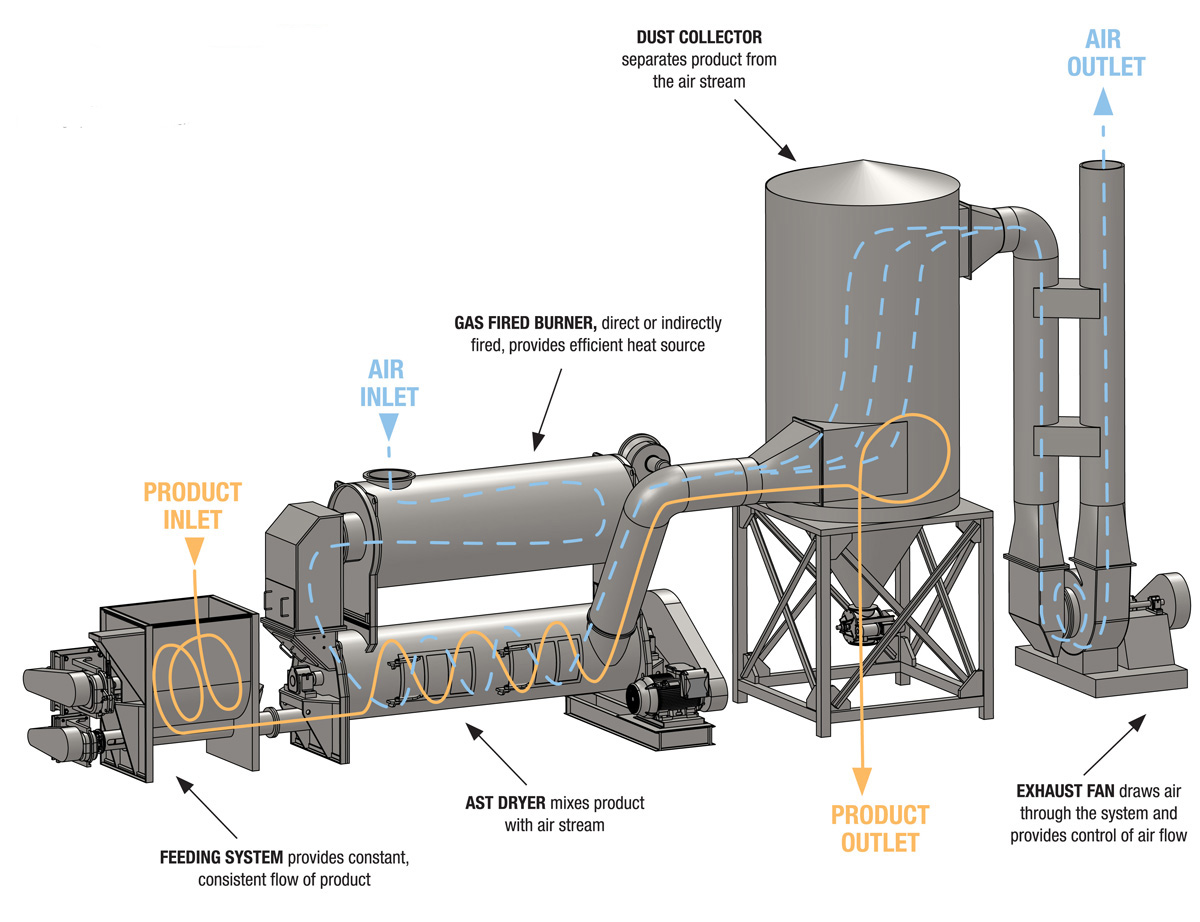

1. Taida drying system consumes less energy. Owing to indirect heating mode, no heat is carried by air. There is one insulation la

2. Taida drying system holds less cost. There is large heat transfer area in effective volume. Disposal period is also reduced. Compared with traditional equipment, Taida drying machine holds small size, which reduces construction area and space.

3. Taida drying machine can be used to dry wide range of materials. It can adopt different thermal medium. It can be used to dry materials which need to be treated by high temperature. There are some common medium, such hot oil, hot water, vapor and cold water. Taida drying machine can both work intermittently and continuously. It can be applied in many fields.

4. It causes less pollution. Without using air, there is less dust materials brought. There is less material solvent evaporated. For those materials which holds pollutants or needs to be recycled, we can adopt closed cycle for the drying system.

5. With low running cost: Taida drying system adopts low speed stirring and reasonable structure. Therefore, there is less abrasion and malfunction during running process.

6. Stable operation: owing to the compression of wedge blade and expansion mixing function, materials can fully contact with heat transfer area. The gradient in axial interval for temperature, moisture and mixture degree is not so big, which can guarantee the stable performance of drying system.

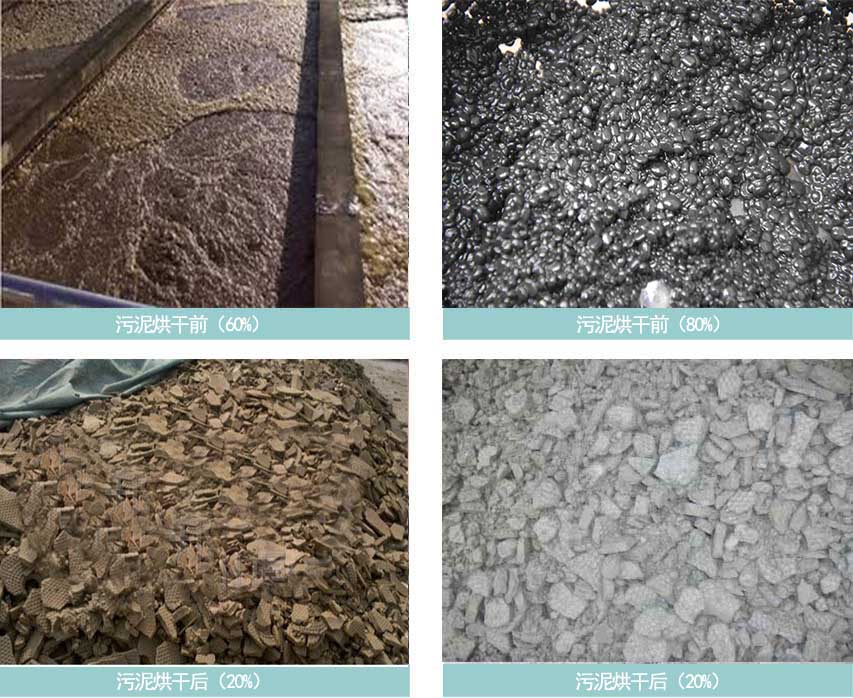

According to quality and features of sludge produced from dyeing textile industry, Taida sludge recycling system can realize resource utilization as much as possible. Taida drying system can also improve the value of sludge. There is a great deal of sludge produced from sewage disposal station. This kind of sludge holds high moisture and organic substances. ba

| No. | Sludge characteristics | Solutions |

| 1 | High moisture content | TDOSC air swept drying system can dry moisture of high-moisture content and viscous materials to standard level. |

| 2 | Caking | TDOSC air swept rotary wing drying system integrates crushing and drying into a whole. |

| 3 | Poor fluidity, feeding jams | Patent technology; designed for high moisture and viscous materials. |

| 4 | Big viscosity, wall sticking and not easy to clean | Patent technology; designed for high moisture and viscous materials. |

| 5 | Materials are easy to lump; moisture hard to evaporate, | Patent technology; designed for high moisture and viscous materials. |

| 6 | Give off odor | With anti-explosion device and good seal structure; add one deordorization device for exhaust gas dust collecting system; |

| 7 | With corrosive components |

A:In raw material system, materials will mix with neutral materials; B: TDOSC air swept rotary wing drying system are made of stainless steel design, if there is no special request from customers. |

| 8 | Feed head easy to be burnt out | Integrated drying body; durable stainless steel design. |

| Revolutionary product, fifth generation drying technology for high moisture and viscous materials!!! | ||

Sales Hotline:0371-67793637

Technical Support:15515557076

Whatsapp:008618539990967

Email:vip@tdaxy.com

Factory Address: No.198, Longding Industrial Park, Lianhua Road, High-Tech Zone, Zhengzhou City

Email:vip@tdaxy.com Technical Consult:86-18539990967

Municipal Sludge Drying Equipment

Viscous Material Drying

All Rights Reserved Zhengzhou Taida Drying Equipment Co,. Ltd