Product Introduction

Steam tube bundle dryer is widely applied to drying loose materials from chemical industry, light industry, food, grain and feedstuff industry, like powder, sheet and flake materials without high viscosity; like white liquor and beer brewing waste in light industry; like pig hair, bone meal ( bone glue) and pig blood ferment powder in meat industry; like pellet and powder fertilizer and inorganic mineral substances in chemical industry; like corn germ, corn fiber and protein powder in starch industry; like carrier in feed industry (broken corn, soybean residue, protein feedstuff and protein powder); like fish and shrimp leftovers and rapeseeds oil industry.

Features of steam tube bundle dryer:

Product Superiority

Characteristics of new type steam tube bundle dryer

1. Shaft adopts integrated processing structured: rotor spindle is processed by large-scale boring lathe to make sure concentricity, guarantee stable running process and expand service life.

2. Self-aligning sliding in conjunction with bearing design: one end adopts SKF self-aligning bearing and the other end adopts special designed bearing, which makes whole system smoother.

3. Automatic lubrication system: equipped with no-oil alarming system in order to protect bearing.

4. Tube bundle adopts superior texture and special processing craft. Tube bundle adopts superior boil steel and expanding process for firm connection.

Advantages of new steam tube bundle dryer:

1. Low heat and electricity consumption; it only needs 1.2 to 1.4 ton steam for evaporating one-ton moisture.

2. Wide application range: large evaporation capacity; can also be used to dry high moisture raw materials.

3. Strong technical and R&D team: customize according to customers’ specific demands. Different combination among shovel plate, pushing plate and discharging plate can be used to deal with various raw materials. We will assist customer to reach best drying curve and best drying effect.

4. Combination between damper plate and returning device: reach to highest heat exchanging efficiency in shortest retention time.

5. Wide adaptability of drying parameters (drying time can be adjusted according to different materials’ requirements), high automation level; can work both continuously and discontinuously in order to adapt to utilization crafts.

6. Raw materials are dried under closed inner chamber in negative pressure state; clean work environment, pollution free and low noise. Owing to less auxiliary machines, this steam tube bundle dryer occupies less area.

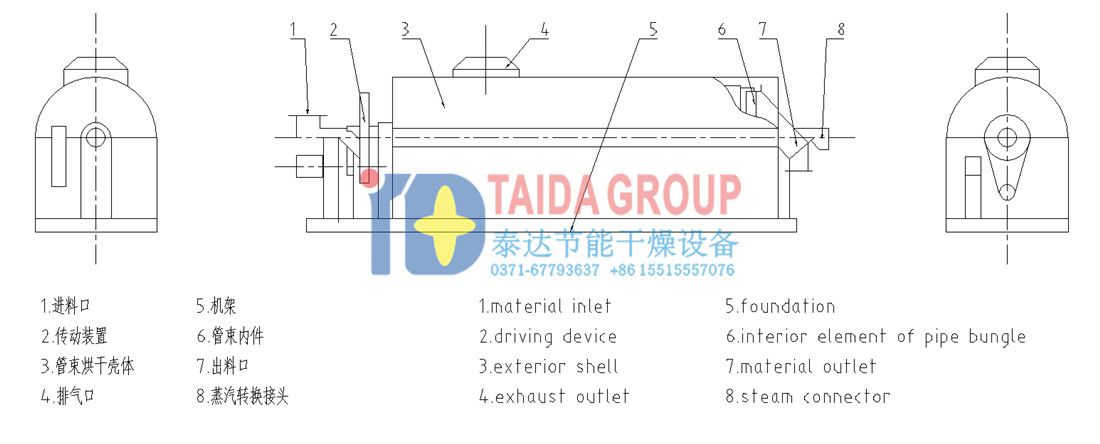

Working Principle

Taida new steam tube bundle drying system working principle

Steam tube bundle dryer takes advantage of internal high-temperature tube bundles which rotate slowly inside to reach moisture evaporation aim. It is a kind of indirect contact dryer. Firm structure is equipped with rotary heating bundles with oblique shovel. Steam enters tube through rotary joint. After heat exchanging heat, steam will become condensed water and be discharged out. Moisture in raw materials will become steam outside tube owing to heat and be discharged out by dehumidification fan. Raw materials are scooped up by rotary shovel and form material curtain. Materials will uniformly fall on external surface of heating tube. Shovels are distributed in spiral line. While efficiently exchanging heat, raw materials will be driven forward to discharging outlet. Finally, dried materials will be discharged out.

Technical Parameter

| Model |

Heat transfer area (M2) |

Output capacity (T) |

Overall dimensions (mm)L×W×H |

Power (KW) |

| GZG90 | 90 | 0.28-0.36 | 7647×1802×2628 | 7.5 |

| GZG150 | 150 | 0.45-0.6 | 9078×1862×2680 | 15 |

| GZG300 | 300 | 0.96-1.2 | 10520×2410×3150 | 22 |

| GZG400 | 400 | 1.3-1.6 | 10805×2660×3665 | 30 |

| GZG500 | 500 | 1.6-2 | 11380×2922×3994 | 37 |

| GZG600 | 600 | 1.9-2.4 | 12450×2986×4006 | 55 |

| GZG700 | 700 | 2.2-2.8 | 12306×3162×4584 | 75 |

| GZG800 | 800 | 2.6-3.2 | 12860×3382×4430 | 90 |

| GZG900 | 900 | 2.8-3.6 | 13810×3382×4430 | 90 |

| GZG1000 | 1000 | 3.2-4 | 14310×3500×4206 | 110 |

| GZG1200 | 1200 | 3.8-4.8 | 15480×3746×4900 | 132 |