Product Introduction

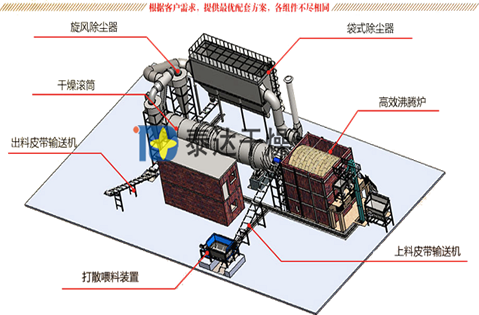

For biomass drying system, we have two types for customers' choice, single pass and multi-pass dryer. Single-pass biomass dryer series produced by Zhengzhou Taida Drying Equipment Co Ltd is composed of front and rear gland head, integrated rotary drum, rotary wing dispersing shaft and central lifting device. This kind of dryer is mainly suitable to deal with sawdust, wood blocks, fruit residues, vinasse/brewing wastes, palm silk and other biomass raw materials. A Present sold multi-pass biomass dryer is our third generation product featured by intelligence, energy conservation and environmental protection. At present, we have set many customer sites and enjoyed good fame at home and abroad. We also obtain great achievements in foreign market expanding. Taida has produced famous brand influence and set many project among major five continents.

Features of steam tube bundle dryer:

Product Superiority

Features of new single-pass biomass dryer:

1. Adopt hot air furnace designed with sedimentation temperature regulation chamber as heat source in order to effectively avoid drum fire phenomenon; whole running process is safer.

2. Low investment, quick drying effect, total investment cost is only one sixth of foreign imported products.

3. Matched with new type energy-saving hot air furnace, it is characterized by high efficiency, low energy consumption, easy thermal control, and simple operation. Coal consumption is reduced about 60%. With high insulation efficiency, low energy consumption and long service life.

4. Dryer is equipped with rotary wing dispersing shaft internally, which can improve heat exchanging efficiency and effectively disperse raw materials.

5. Single pass dryer adopts new transmission device, which can stability and adjustability. Meanwhile, working condition safety of driving motor can be protected.

6. Discharging system of drum adopt thorough seal design, which can effectively avoid air leak and fly dust.

7. Matched with advanced purification technology and efficient dust collector, whole system consumes less electricity.

8. Adopt frequency conversion to control raw material flow. Final moisture can be flexibly controlled.

Working Principle

Single-pass biomass dryer working principle

Single-pass biomass dryer working principle

Through raw material system, wet materials are added into drying machine. Hot air after temperature regulation will enter dryer after sedimentation. Under the function of dispersing blades of feeding end, materials will be distributed in whole drying chamber in diffusion state. Moisture in raw materials will be brought out through heat exchange between hot air and raw materials. Meanwhile, large lump raw materials will be scattered under the function of rotary wing shaft and move forward under the function of drum rotation. After fast drying and dewatering process in first stage, raw materials will enter constant dehydration stage where there is central combined lifting device designed. Hot air will repeatedly exchange heat and absorb moisture with raw materials from different angles in maze-like structure. In this way, whole system can not only reach to uniform drying effect, but also avoid influence to drying quality caused by high temperature rise. Finally, dried products will be discharged out from discharging end and sent to finished products silo after cooling process. Tail gas after heat emission and moisture absorption will reach purification standard through primary and secondary dust removal device. Then, purified tail gas will enter exhaust heat recycle system or will be discharged to atmosphere.

Technical Parameter

| Model |

Diameter (mm) |

Length (mm) |

Output capacity (t/h) |

Initial moisture | Final moisture |

| TDOSB-S | 800 | 10000 | 0.7 | 40-65% | 8-15% |

| TDOSB-S | 1000 | 10000 | 1.1 | 40-65% | 8-15% |

| TDOSB-S | 1200 | 12000 | 1.5 | 40-65% | 8-15% |

| TDOSB-S | 1500 | 12000 | 2 | 40-65% | 8-15% |

| TDOSB-S | 1800 | 15000 | 3 | 40-65% | 8-15% |

| TDOSB-S | 2000 | 18000 | 4 | 40-65% | 8-15% |

| TDOSB-S | 2200 | 18000 | 5 | 40-65% | 8-15% |

| TDOSB-S | 2600 | 20000 | 7 | 40-65% | 8-15% |

| TDOSB-S | 3000 | 20000 | 9 | 40-65% | 8-15% |

| TDOSB-S | 3200 | 22000 | 11 | 40-65% | 8-15% |

| TDOSB-S | 3500 | 22000 | 13.5 | 40-65% | 8-15% |

| TDOSB-S | 3500 | 24000 | 15.8 | 40-65% | 8-15% |

| TDOSB-S | 4000 | 24000 | 19 | 40-65% | 8-15% |

| TDOSB-S | 4000 | 26000 | 22.5 | 40-65% | 8-15% |

| TDOSB-S | 4500 | 24000 | 25.8 | 40-65% | 8-15% |

| TDOSB-S | 4500 | 26000 | 28.125 | 40-65% | 8-15% |

| TDOSB-S | 5000 | 26000 | 34 | 40-65% | 8-15% |

| TDOSB-S | 5000 | 30000 | 39 | 40-65% | 8-15% |

| TDOSB-S | 5600 | 28000 | 45 | 40-65% | 8-15% |

| TDOSB-S | 5600 | 30000 | 50.6 | 40-65% | 8-15% |

| TDOSB-S | 6000 | 30000 | 56 | 40-65% | 8-15% |