Present development situation of toxic sludge drying system

Different industries produce different industrial toxic sludge. At present, main industrial sludge contains electroplating sludge, steel making sludge, alumina sludge, oily sludge, chemical sludge, papermaking sludge, dyeing textile sludge and leather sludge. Generally speaking, industrial sludge always contains toxic and harmful matters. Without proper disposal, these harmful matters will pollute underground water and ecological environment.

In some regions which have been seriously affected by industrial pollution, sludge holds complex ingredients. Different from silt precipitated in river way, sludge is produced from waste water disposal. It contains organic residues, germs, inorganic pellets, heavy metal and colloid sludge. Sludge from textile factory, dismantling industry and chemical industries is toxic sludge.

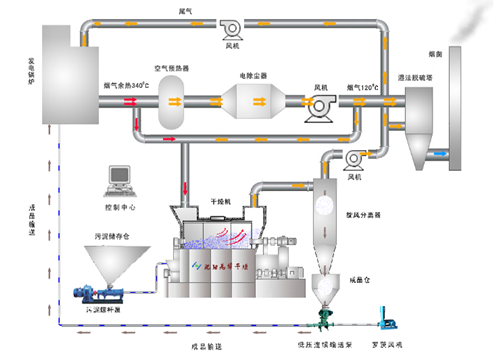

At present, there are some popular methods to deal with sludge, such as sanitary landfill, land utilization, incineration and sea filling. But, these methods will bring about problems on secondary pollution, atmosphere pollution control and investment. Based on real situation of sludge produced, we think it is the most reasonable method to combust dried sludge. There are some popular drying technologies, such as hot air drying, steam drying and flue gas drying. Without enough steam source, it is hard to realize steam drying process. If you want to adopt low-temperature large air volume, the equipment will occupy much area. Combination of technical parameter plays a vital role in drying effect. Relatively speaking, heat source for hot air drying has a wide range. The operation process is relatively simple.

Taida energy-saving toxic sludge drying system solution

Common sludge drying solution

Sludge drying: this system can be used to half-dry or full-dry sludge. Cooperated with incineration, landfill and other integrated system, Taida sludge drying system can make the reduction, harmlessness and stabilization of sludge come true.

Sludge power generation: establish sludge incineration comprehensive utilization project.

Sludge makes bio char: for 10-ton sludge with 80% moisture content, after dry distillation, sludge can be used to produce 1-ton bio char. This method cannot only reduce the amount of sludge, but also avoid secondary pollution. It is known that bio char produced in the process can be widely applied for soil improvement.

Has been specialized in sludge drying technology for many years, aimed at toxic and harmful sludge produced in industries, combined with real situations in different fields and summarizing up traditional disposal methods, Zhengzhou Taida group developed out a set of complete set of harmlessness and recycling system for toxic sludge.

Characteristics of Taida desulfurized gypsum calcining process:

1. Customers can choose flexible heat sources, such as coal, electricity, microwave, natural gas, LPG and diesel.

2. After drying, final products can be used as fuel for boiler. dried sludge can also be used to make bricks, landfill and compost to realize

3. Environmental friendly and energy-saving;