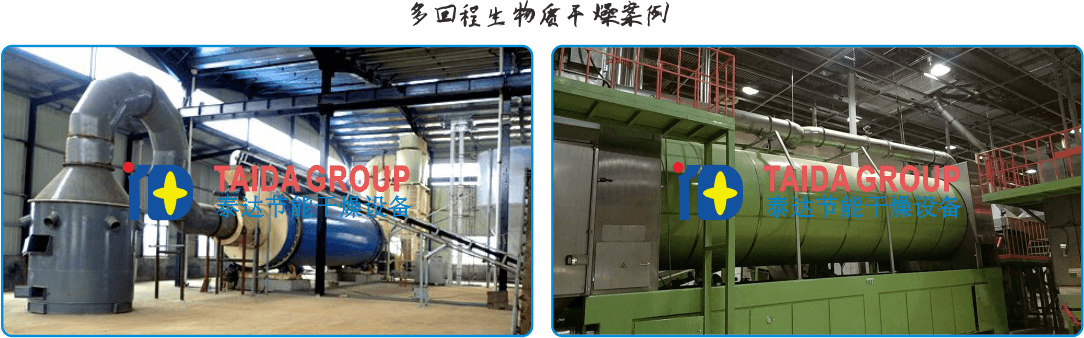

Product Introduction

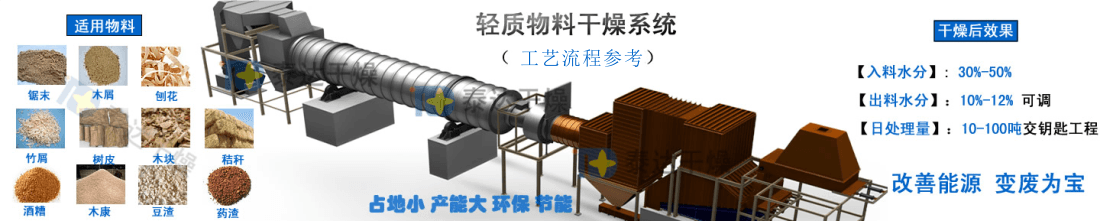

Multi-pass biomass dryer is mainly designed for wooden by-products, such as wood shavings, wood chips, wood powder, sawdust, crushed wood blocks, tree branch, leaves and other biomass raw materials. Based on continuous R&D, Taida multi-pass biomass dryer has achieved times technological upgrades. Present sold multi-pass biomass dryer is our third generation product featured by intelligence, energy conservation and environmental protection. At present, we have set many customer sites and enjoyed good fame at home and abroad. We also obtain great achievements in foreign market expanding. Taida has produced famous brand influence and set many project among major five continents.

This series drying can be matched with continuous carbonization furnace and establish a carbonization production line. It can also work with pellet machine and establish biomass pellet fuel production line. By cooperation with plate processing equipment, compound plate production line can be established. Zhengzhou Taida Drying Equipment Co Ltd can supply various auxiliary machines in above production lines, like wood powder machine, screen machine, dryer, pellet machine, conveyor, packaging machine and dust collecting equipment. At present, with numerous working sites in England, Italy, Russia, Israel, Greek, Morocco, Australia, Malaysia, Laos, Sri Lanka, India and Chile, Taida influence become greater and greater. Our business has been expanded fast and gained superior achievements.

Product Superiority

Features of new biomass multi-pass dryer:

1. Automatic control which can guarantee stable drying effect; with automatic impurities removal function; impurities will not enter following steps.

2. Consumes less energy, produce less emission and cost less investment expense.

3. Drum insulation thermal efficiency can be improved by more than 70%.

4. Adopt tail drive, transmission is more stable; it can change riding wheel slip phenomenon.

5. Optimized structure, low occupation area, civil work investment can be reduced about 50%. Low energy consumption, electricity consumption can be reduced about 60%.

6. Distribution of lifting device is updated, which can effectively improve drying time and drying quality.

7. Temperature of tail gas is low, which can extend service life of dust collecting machine and make whole process continue constantly.

8. Equipped with new energy-saving heat source, whole process is characterized by high efficiency, low energy consumption, easy and stable operation. Energy consumption can be reduced about 60%.

Working Principle

Structure advantage of Taida multi-pass biomass drying system

Different from single-pass biomass dryer, new multi-pass biomass dryer adopts three-pass rotary drum which is also called three la

Taida new multi-pass biomass dryer working principle

Considering from working principle, multi-pass biomass dryer belongs horizontal dryer. It mainly takes advantage of heat exchanging. Biomass raw materials will fully contact with hot air under function of dryer structure. Moisture will be evaporated in high temperature condition. Under the function of inner lifting plate, biomass materials will move to the other end while exchanging heat. Counter-flow drying process is carried out in the middle drum while raw materials will be lifted and driven forward repeatedly. Materials can absorb heat emitted from both middle drum and inner drum so that to reach to best drying effect. Materials will enter external drum after leaving end of middle drum. Materials will move in the state of rectangular multiloop state. Qualified materials will move rapidly under the function of hot air and discharged out of dryer drum. Unqualified materials cannot move forward fast owing to own weight. Materials will be fully dried in the rectangular lifting plate in order to finish drying aim.

Technical Parameter

| Specifications |

Output capacity (T/H) |

Initial moisture (%) |

Final moisture (%) |

Power (KW) |

Occupation area (㎡) |

| OSB-T | 1-1.5 | 40-50 | 12-16(adjustable) | 26 | 5*15 |

| OSB-T | 1.5-2 | 40-50 | 12-16(adjustable) | 32 | 5*18 |

| OSB-T | 2-3 | 40-50 | 12-16(adjustable) | 39 | 6*22 |

| OSB-T | 3-4 | 40-50 | 12-16(adjustable) | 61 | 8*16 |

| OSB-T | 4-5 | 40-50 | 12-16(adjustable) | 68 | 8*18 |

| OSB-T | 5-7 | 40-50 | 12-16(adjustable) | 84 | 10*20 |

| OSB-T | 7-10 | 40-50 | 12-16(adjustable) | 102 | 10 |