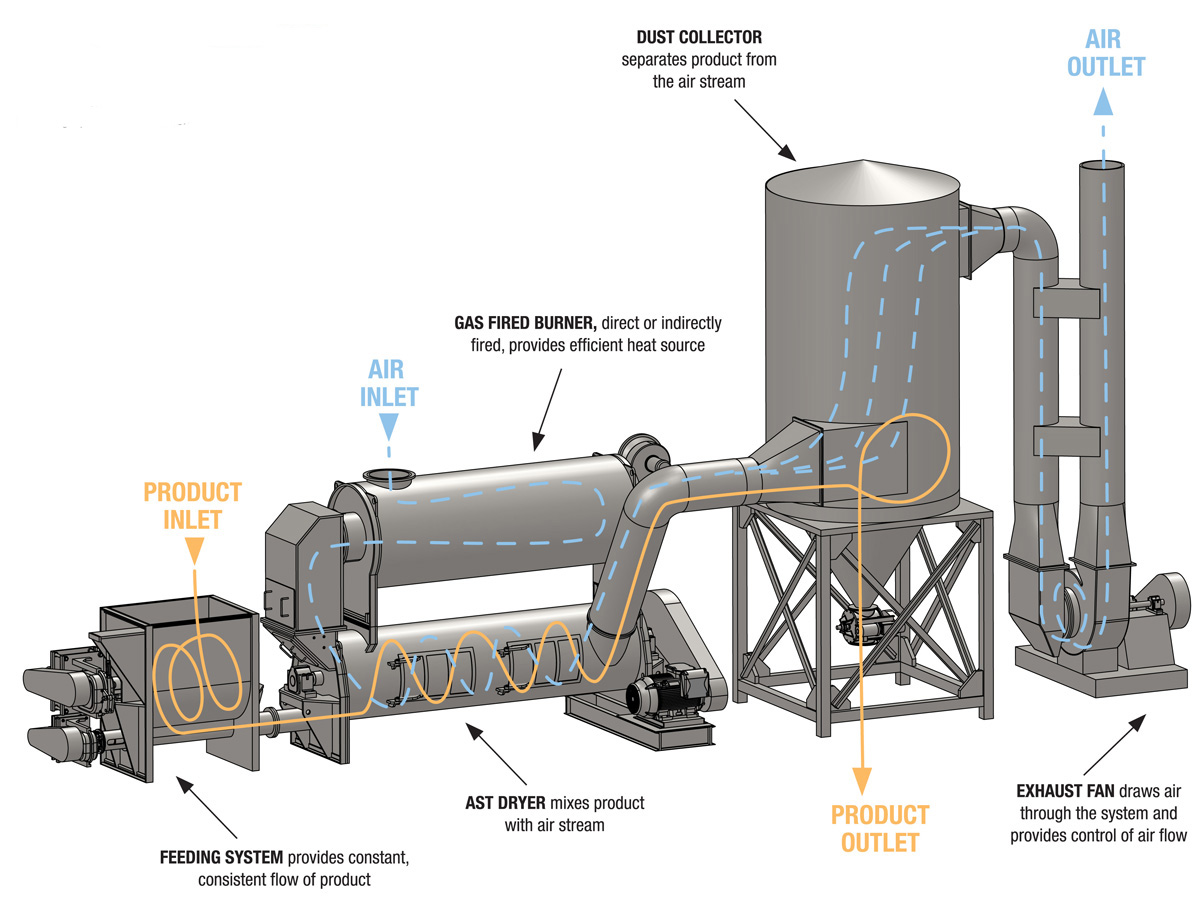

Aimed at special qualities of sludge, Taida professional air-swept dryer combines advantages of traditional drying machines. It can thoroughly solve difficulties in pharmacy sludge disposal process.

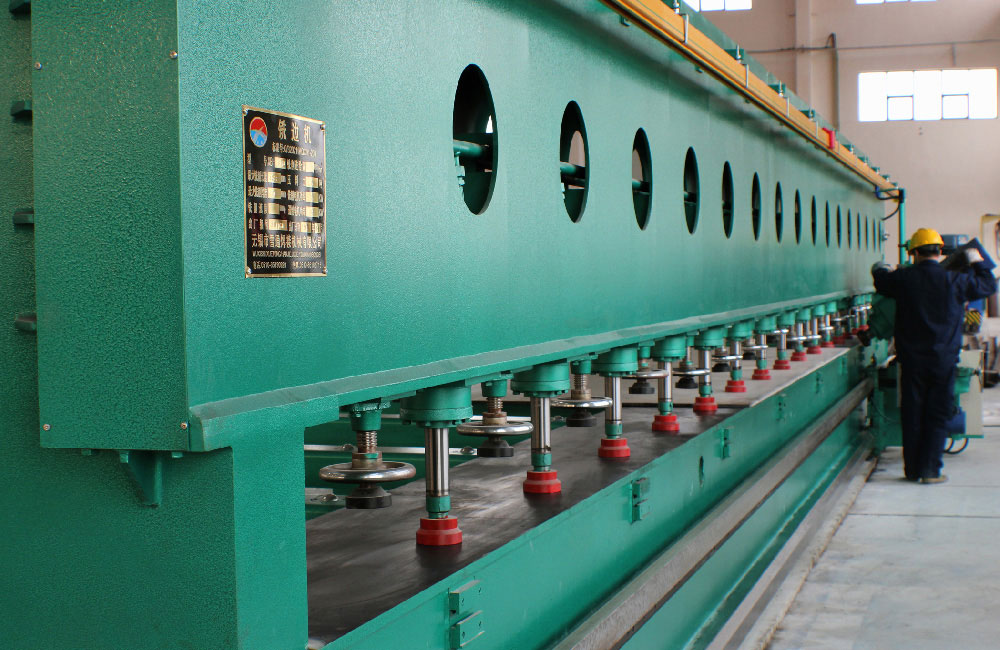

【Application range】:

it can be applied to various pharmaceutical factories. It also can be applied to dealing with viscous and high moisture materials.

【Applicable materials】:

it is suitable for dealing with various sludge, pharmacy sludge, industrial sludge and etc. it has been successfully applied in chemical industry, petrification industry, fuel and industrial sludge field.