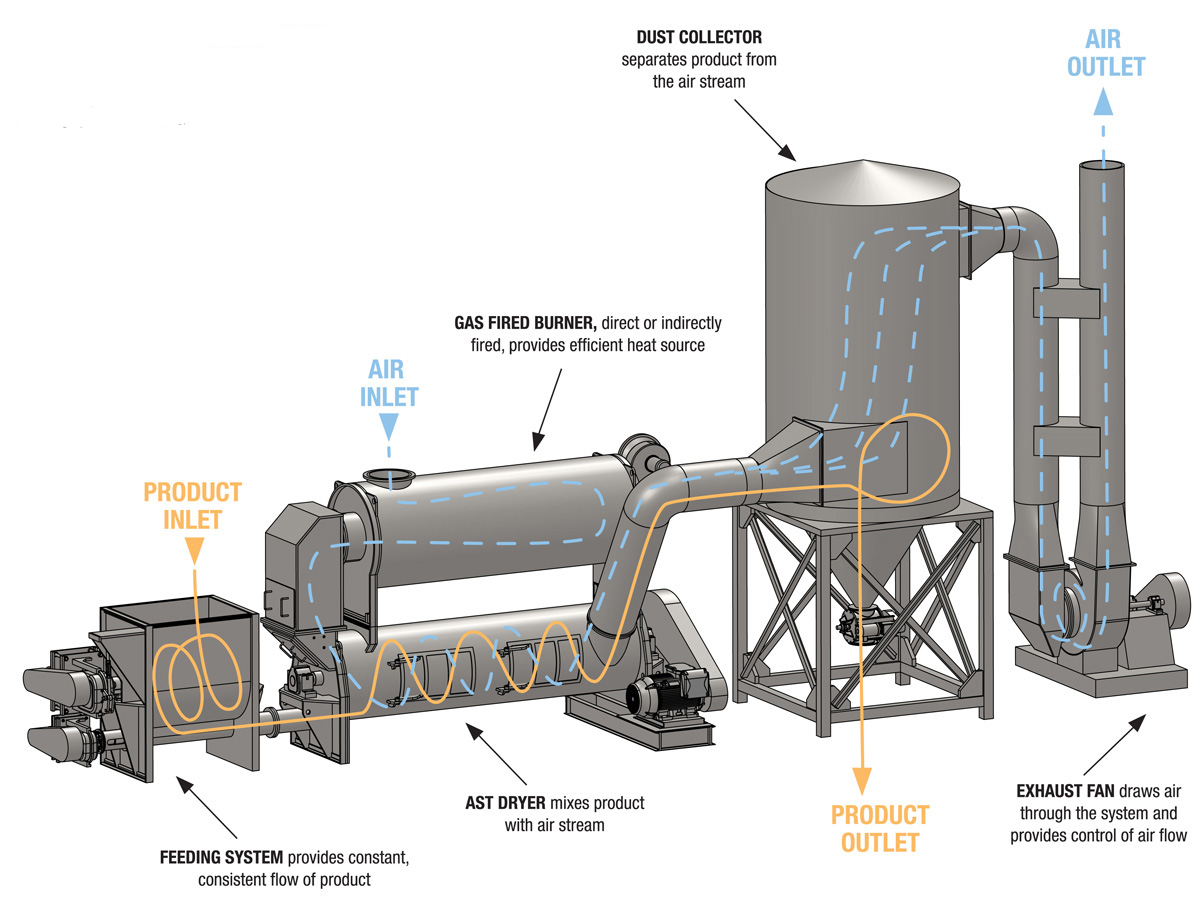

Aimed at sludge from leather and tannery industry, Zhengzhou Taida developed out a set of complete leather sludge drying system which is ba

【Application range】: leather sludge from various tannery industries, denitration sludge from various boiler enterprises. It can also be used to dry high moisture and viscous materials.

【Application materials】: various sludge, desulfurized gypsum, toxic and heavy me