In china, food industries, such as alcohol, starch sugar, gourmet powder industry and citric acid industry always apply grain as raw materials. But, the utilization efficiency of raw materials is low. 30% to 40% raw materials will become waste water and waste residues at least. There is great amount of alcohol residues wasted every year. The waste liquid from alcohol production will produce much pollution to environment.

【Application range】:

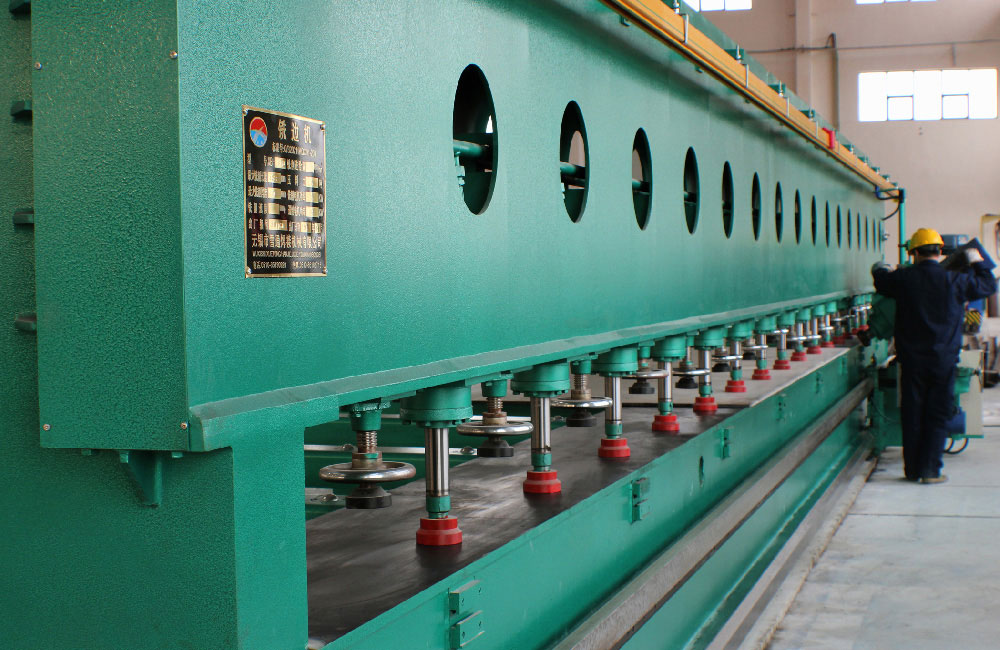

suitable to apply in various winery, brewery house and feedstuff industries to deal with viscous and high moisture content materials.

【Applicable materials】:

can be applied to various vinasse, brew grain, distiller grain and fermented vinasse. It has been widely applied to brewery, wine and feed factories.