Welcome to Official Website of Zhengzhou Taida Drying Equipment Co,.Ltd!Please call 0086-371-86565118 for more information.

- Bean Dregs Drying

- Rotary Wing Drying System

- Brewer Grain Drying

- Sewage Sludge Drying

- Pond Sludge Drying

- Toxic Sludge Drying Solution

- Power Plant Sludge Drying

- Papermaking Sludge Drying

- Electroplate Sludge Drying

- Dyeing Textile Sludge Drying

- Leather Sludge Drying Solution

- Heavy me

tal Sludge Drying - Paint Sludge Drying

- Pharmacy Sludge Drying

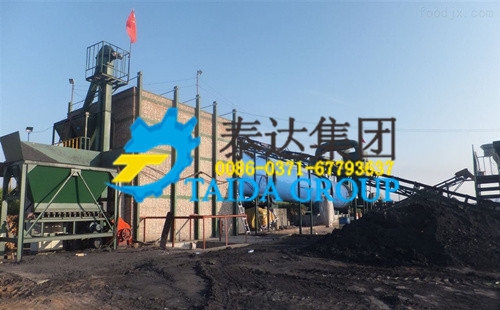

- Coal Slurry Drying Solution

- Municipal Sludge Drying

- Silt Dehydration Solution

- Bio-sludge Alkaline Stabilizati

- Desulfurized Gypsum Drying